Save Weight, Save Money, Ride More

Many things are sold by weight – produce, precious metals, spices – but it might surprise you to learn that there is a clear correlation between weight and cost when it comes to building electric vehicles. The shortest explanation is that heavy vehicles require bigger batteries to deliver enough power, and the batteries themselves add considerable weight while also being very costly. This post will discuss in greater detail why Graft is dedicated to offering lightweight EVs and what the performance and maintenance benefits are.

EVs Tend to Be Heavy

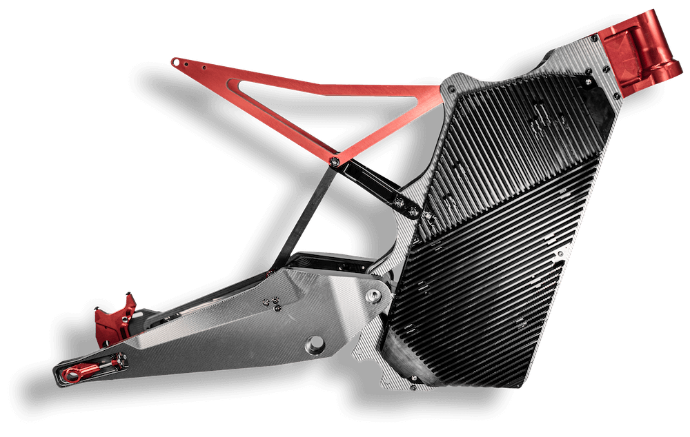

Modern, mass market electric vehicles are commonly 25-50% heavier than their gas-powered equivalents and this holds true for both four-wheeled and two-wheeled EVs. This is caused by the current energy density of batteries. As we have long been familiar with the weight and kind of energy density that electric drive trains and battery systems require, at Graft one of our top priorities after safety and reliability is weight reduction. We set a target for all of our vehicles to weigh 50% of the comparable traditional gasoline vehicle, so we are making a decisive turn away from convention in the way we are building our off road vehicles.

Where Lower Weight Meets Higher Value

So as weight goes up, the size of the battery needs to increase in tandem in order to cover the same distance as a lighter vehicle with a smaller battery pack. When we keep the vehicles lighter, we can keep battery prices down while at the same time improving the quality of ride as well as the handling of the vehicle at times when it’s not being ridden, such as when loading onto trailers or cleaning.

Stay Agile and Ride Longer

So often when we go riding, we see riders on gas bikes that are 450 or even 300 cc. When they drop that bike two or three times on a hill climb, they're completely worn out after standing the bike up and repositioning it. With our bike being half the weight, riders can carry it over a log or reposition it to make another attempt at a hill climb. In deep sand, we can simply lift the rear tire out of the sand and get moving again. All of these weight advantages pay off not just in terms of range and cost, but from the exertion and the energy that the rider is going to spend on tricky or difficult terrain.

Off road vehicle manufacturers are generally increasing the weight and making vehicles tougher and tougher every year, particularly in the UTV and ATV markets. Many manufacturers are opting for larger ball joints, larger suspension arms to get the vehicles to live, we take a unique and opposite approach to getting these parts to live. We find that reducing the weight reduces the load on the ball joints and also means we can run lighter tires and they last longer. We don't need to run a thick six- or eight-ply tire. So with the Graft ATV, which weighs just 200 pounds, we're able to use a much lighter weight package but still offer all the durability you would expect because we're gliding over the obstacles instead of banging into them.

No Compromise on Power

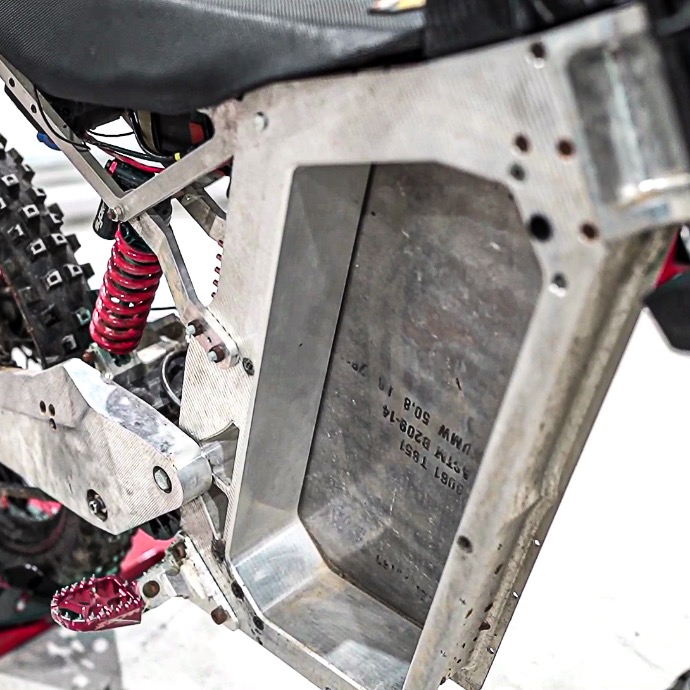

The weight of the EO.12 means that recovering from a drop or getting unstuck is much more manageable for a single rider to do several times on a long ride, if needed. Overall, the bike puts out a bit lower power than some of these heavier competitors, but in terms of power-to-weight ratio, the EO.12 is in the same class. This lower weight means we do offer a little bit smaller battery pack, but our battery swapping technology allows you to ride to one, two, or even three hours on a single charge. Circle back to home base or stop for lunch, spend one minute to swap out the battery and continue on your ride. Or if you're doing laps like a hare scrambles race, you come in on your pitstop, change batteries and you're back out racing. Getting stuck in the mud a couple times with a 250-pound bike will wear down any rider and that kind of limitation shortens your ride time.

Simple Design for Reduced Maintenance

A lighter bike simply puts less wear and tear on components. Our suspension goes much longer before rebuilds because of our light weight and the wheels, tires, all of the components just last longer. On top of that, we've done a simple single-stage reduction on our drive train, we have no belts, no gearboxes that can leak - just a single-stage reduction gives us the most reliability, simplest drive train at the lightest weight.